2025-03-26T04:28:33

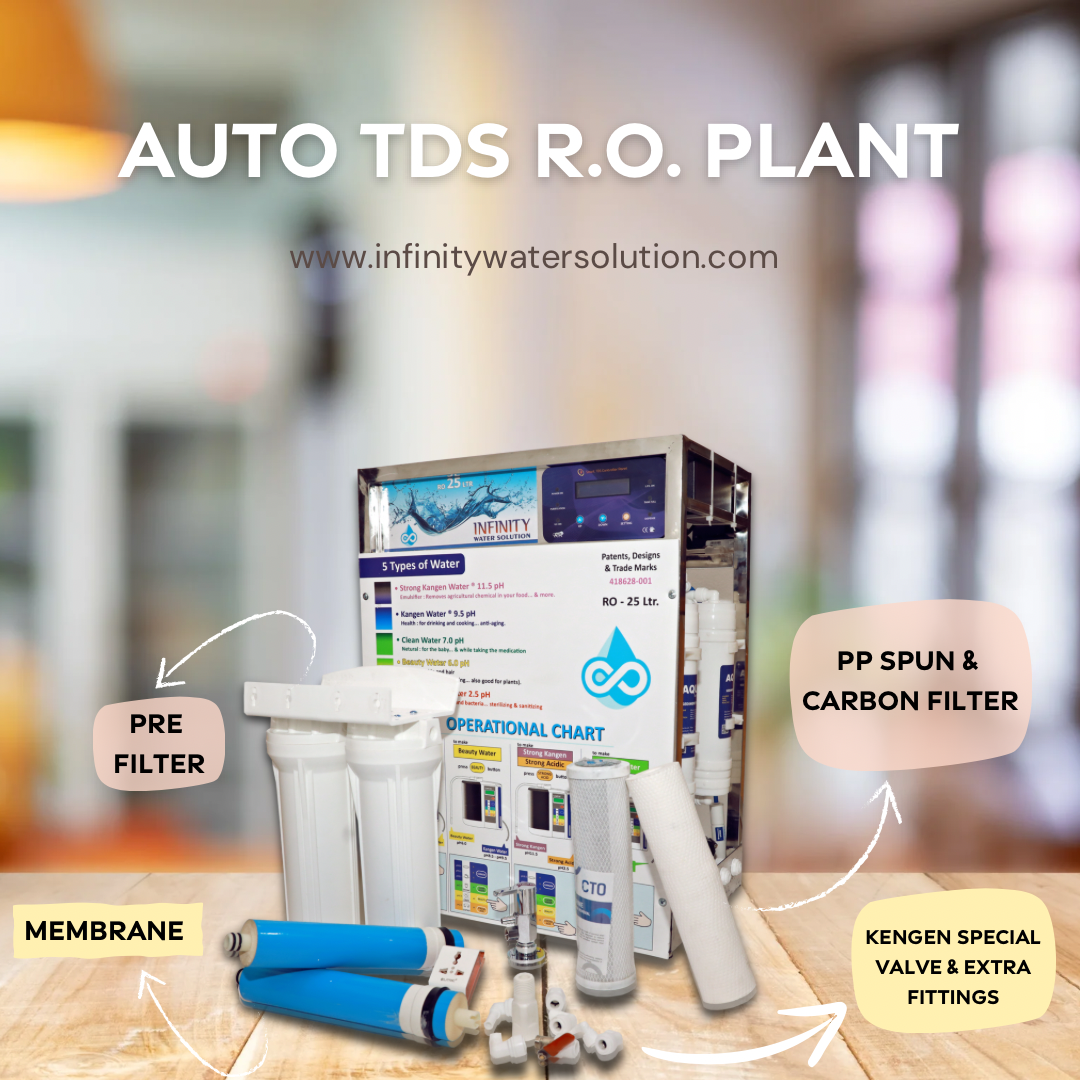

Auto tds controller ro system manufactur in Rajkot auto tds controller ro manufacture in Rajkot Auto T D S Ro plant Manufacturee in Rajkot To automate a TDS (Total Dissolved Solids) management process for a Reverse Osmosis (RO) water purification system, you generally need to integrate a monitoring and control system that adjusts the process based on real-time TDS readings. Here’s a step-by-step guide to automate your RO plant's TDS management: 1. Install a TDS Sensor Install a TDS sensor in the output water stream of the RO system. This sensor will provide real-time data about the water quality, including the concentration of dissolved solids. You can use sensors like the EC (Electrical Conductivity) sensor, which directly correlates to TDS levels. 2. Connect the Sensor to a Controller Use a Programmable Logic Controller (PLC), SCADA system, or a microcontroller (e.g., Arduino, Raspberry Pi) to read data from the TDS sensor. The PLC will receive the TDS values, allowing you to automate the control of valves, pumps, and other components of the RO system. 3. Set TDS Thresholds Define the TDS levels at which the system needs to be adjusted (e.g., if TDS exceeds 300 ppm, activate a flush cycle or trigger a cleaning process). Set upper and lower limits for acceptable TDS. If the value goes beyond the predefined thresholds, the system should trigger corrective actions (e.g., flushing, chemical dosing, or adjusting water flow). 4. Automated Control System Setup Flush Control: If the TDS level rises above the threshold due to membrane fouling or concentration polarization, an automatic flushing system should be activated. Chemical Dosing: Based on TDS readings, automated chemical dosing pumps (such as anti-scalant or cleaning chemicals) can be activated. Pump Speed Control: In some systems, adjusting the speed of feedwater pumps or permeate pumps can influence the TDS level in the output water. 5. Data Logging and Alerts Enable data logging to track TDS over time. This can help monitor trends and predict maintenance needs. Set up alerts (email/SMS) that notify operators or engineers when TDS values go outside of acceptable ranges, triggering maintenance or operational checks. 6. Integration with SCADA/IoT If your RO plant has a SCADA or IoT-based monitoring system, integrate the TDS sensor to enable real-time visualization of water quality data. This provides operators with instant feedback and the ability to control the system remotely. You could also implement a dashboard to visualize parameters like TDS, pressure, flow rates, and pump statuses, allowing operators to monitor the system efficiently. 7. Regular Maintenance & Calibration Periodically calibrate your TDS sensors to maintain accuracy. Sensors may drift over time and affect the automated responses. Ensure your automated cleaning cycles (e.g., CIP - Clean in Place) are scheduled properly based on TDS readings to keep the RO membranes in optimal condition.

Have a question? Ask here!

Required fields are marked *